Selection of RF Coaxial Connector.

Article contributed to by Yongys yin

When selecting RF coaxial connector, users should consider both performance requirements and economic factors, performance must meet the requirements of system electrical equipment, and economically must meet the requirements of value engineering. In the selection, it is mainly considered from the following four aspects.

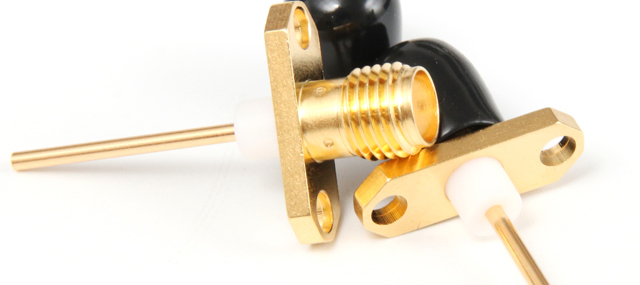

1. Connector interface (SMA, SMB, N).

2. Electrical performance, installation and cables.

3. Termination form (PC board, electrical construction, panel, etc.).

4. Mechanical construction and coating (military, commercial)

A.Connector interface

Connector interfaces are usually determined by their applications, but at the same time meet electrical and mechanical performance requirements.

BNC connector uses bayonet type for RF signal connection with frequency lower than 4GHz, and is widely used in network system, instrument and computer interconnection field.

Except for threaded connection, the interface of TNC is similar to that of BNC, which can still be used in 4GHz and has excellent performance under vibration conditions.

SMA threaded connector is widely used in aviation, radar, microwave communication, digital communication and other military and civil fields. Its impedance is 50 ohms, the frequency of flexible cable is less than 12.4 GHz, and the maximum of semi-rigid cable is 26. 5GHz .

The plug-in structure of SMB is smaller than SMA, which is easy to connect quickly. It is mainly used in the field of digital communication. It is a replacement product of L9. 50 ohms meet 4GHz and 75 ohms are used in 2GHz.

SMC is similar to SMB in that it has threads to ensure more reliable mechanical properties and a wider frequency range, which is mainly used in military or high vibration environments.

N-type threaded connectors use air as insulating material, low cost, impedance of 50 ohms or 75 ohms, frequency up to 11GHz, usually used in regional networks, media transmission and test instruments.

MCX series connectors are small in size and reliable in contact, and are suitable for use in the narrow space inside the equipment, and have a wide application prospect in the field of post and telecommunications.

B. Electrical performance, installation and cables.

(1) Impedance.

The connector should match the impedance of the system and cable. It should be noted that not all connectors have interfaces that meet the impedance of 50 ohms or 75 ohms and that impedance mismatches can lead to system performance degradation.

(2) Voltage.

Ensure that the maximum voltage value of the connector is not exceeded in use.

(3) maximum operating frequency.

Each connector interface has a maximum frequency limit. Some commercial designs for 75 ohms have a minimum frequency limit. In addition to electrical performance, each type of interface has its own uniqueness. For example, BNC is connected by bayonet, which is easy to use and low price, and is widely used in low performance electrical connection. SMA and TNC series are threaded connections, which meet the requirements of connectors in high vibration environment. SMB has the function of fast connection and disconnection, so it is more and more favored by users.

(4) Transmission cable.

TV cables are usually used in systems that only consider impedance because of their small shielding effect.

TV flexible cable is the deformation of TV cable, it has relatively continuous impedance and good shielding effect, can be bent, the price is low, it is widely used in the computer industry, but it can not be used in systems with high shielding performance.

The shielded flexible cable eliminates inductance and capacitance and is mainly used in instruments and buildings.

Soft coaxial cable has become the most common sealed transmission cable because of its special performance.

Coaxial means that the signal and grounding conductors are on the same axis, and the outer conductor is made up of fine braided wires, so it is also called braided uranium cable. This cable has a good shielding effect on the central conductor, and its shielding effect depends on the type of braided wire and the thickness of the braided layer. In addition, it effectively makes up for the poor shielding effect of braided cable at high frequency. Semi-rigid cables are usually used when the frequency is very high.

(5) installation.

There are two main installation methods of connectors:

1. Welding center conductor, rotating shield layer.

2. Crimping center conductor, crimping screen layer.

Other methods are derived from the above two methods, such as welding center conductor and crimping shielding layer. Method 1 is used in situations where there are no special installation tools; due to crimping installation.

The method has the advantages of high working efficiency, reliable termination performance, and the design of the special crimping tool ensures that every cable assembly produced is the same, so with the development of low-cost installation tools, crimping the central conductor, Crimping shields will be increasingly popular.

C. Termination form.

Includes connections to radio frequency coaxial cable printed circuit boards and other connecting interfaces. It is proved that a certain form of connection matches a certain type of cable. Generally, the cables with small outer diameters are connected to small coaxial connections such as SMA and SMB, and the appropriate connectors can be selected with reference to the cable size list.

D. Mechanical structure and coating.

The structure of the connector will greatly affect its price, and the design of each connector includes military standards and commercial standards. Military standard MIL-C-39012 manufacturing, all copper parts, polytetrafluoroethylene insulation, internal and external gold plating, reliable performance. Commercial standards are designed with cheap materials such as brass castings, polypropylene insulation, silver plating, etc.

The connector materials are brass, beryllium bronze and stainless steel. The central conductor is generally coated with gold because of its low resistance, corrosion resistance and excellent tightness.

The military standard requires gold plating on SMA and SMB and silver plating on N, TNC and BNC outer conductors, but because silver is easy to oxidize, many users prefer nickel plating.

The commonly used connector insulation materials are polytetrafluoroethylene, polypropylene and modified polystyrene, among which polytetrafluoroethylene has the best insulation performance, but the production cost is high.

The material and structure of the connector affect the processing difficulty and efficiency of the connector, so users choose the connector with good performance-price ratio according to their own application environment.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian

Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Chinese(Simplified)

Chinese(Simplified) Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Japanese

Japanese Korean

Korean Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh